咨詢(xún)熱線18915268821

Mixing form

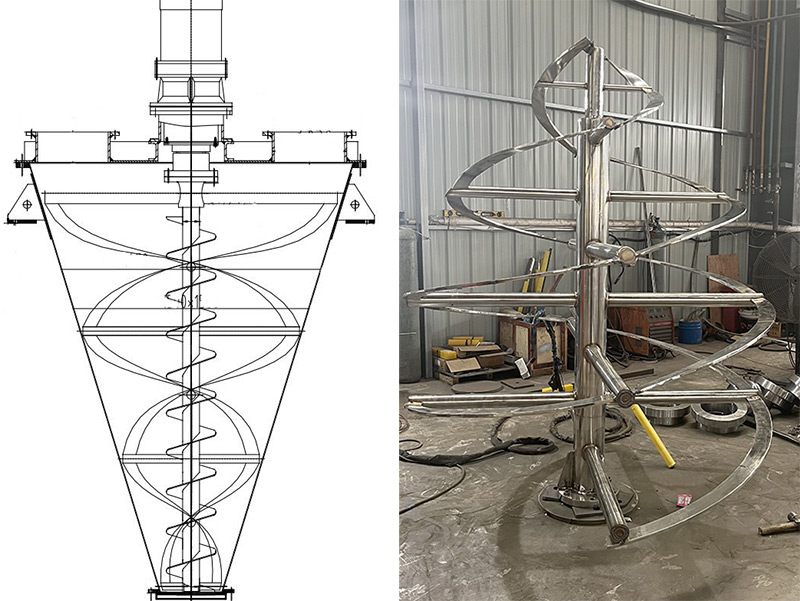

Overview

The ZLDH single cone screw belt mixer is directly connected to the main shaft by a vertical motor through a cycloidal pin wheel reducer, and there are two large and low circles of screw belts on the main shaft. After starting the mixer, the rotating spiral belt moves the material in a bottom-up circular motion along the wall surface in the mixing chamber to lift or throw it up. When the material reaches the center or highest point, it moves downwards by its own weight, causing mutual diffusion, convection, shearing, dislocation, and mixing of the materials in the conical mixing chamber, forcing the materials to undergo all-round spatial irregular composite motion.

Product Features and Applications

The conical spiral belt mixer is applied in the mixing, reaction, drying, and cooling of powder and powder (solid solid), powder and liquid (solid liquid) in chemical, pharmaceutical, pesticide, dye, petroleum, metallurgy, building materials, and other fields. It has the characteristics of small footprint, simple structure, convenient maintenance, and can be equipped with cold and hot interlayers and spraying devices, with clean discharge.

Specification parameters

1. Determine the volume of materials mixed in each batch, ranging from 0.1 to 20 cubic meters, and select equipment of corresponding specifications.

2. Select equipment to make materials, which can be divided into parts that come into contact with the material and parts that do not come into contact with the material. Other components of the equipment should maintain their original materials. The material is determined based on factors such as material properties, working conditions, and hygiene level. Generally, carbon steel and 304/316L/321 stainless steel materials are selected and the surface treatment requirements are determined according to the requirements.

3. Determine the driving capacity of the configuration based on the specific gravity, fluidity, and other properties of the material, as well as the startup standards. Starting standards include: heavy load starting and no-load starting.

4. According to the actual process situation, add auxiliary functional components such as spraying, heating/cooling, etc.

5. Design equipment opening requirements, such as feeding ports, cleaning ports, exhaust holes, etc

6. Select the discharge mode and driving method, including pneumatic, pneumatic, and electric

Important reminder: The selection of equipment is a crucial step, and detailed information on materials and process arrangements should be provided as much as possible, so that our company's professionals can provide you with high-quality technical services.

case diagram