咨詢熱線18915268821

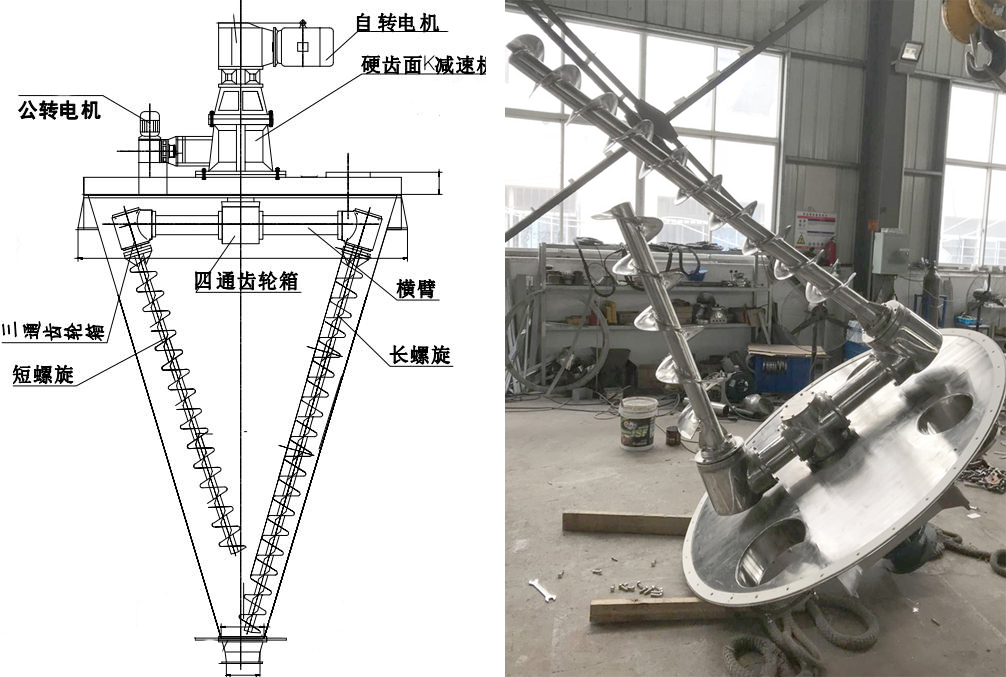

Mixing form

Overview

The ZHJ series conical mixer is a new type of high-efficiency and high-precision mixing equipment composed of a long spiral or two (three) asymmetric spiral stirrers. They not only rotate around their own axis (self rotation), but also use the rotation of the cantilever to orbit the central axis of the conical container and perform planetary motion (revolution) along the inner wall of the conical container; This device repeatedly lifts the material through the rotation of the spiral, generating composite movements such as shear, convection, and diffusion within the cone, thereby achieving the goal of uniform mixing. This machine can also produce various special forms such as heating, cooling, positive pressure, vacuum, etc. according to user requirements.

A. Mixing effect

The standard conical mixer has two mixing screws, one long and one short. In practical applications, single (one long screw) and three (two short and one long symmetrically arranged) screws can also be used according to the equipment specifications.

B. Cooling and heating

Various types of jackets can be added outside the mixer barrel to cool or heat the material by injecting hot and cold media into the jacket; Generally, cooling water is pumped into industrial water, and heating water can be pumped into steam or heat transfer oil.

C. Mixing with liquid

Insert a spray pipe at the intermediate shaft position of the mixer and connect it to the atomizing nozzle to achieve liquid mixing; By selecting specific materials, acid and alkaline liquid materials can be added for powder liquid mixing.

D. Pressure resistant type

The cylinder cover can be made into a head type, and the cylinder body can be thickened to withstand positive or negative pressure. At the same time, it can reduce residue and facilitate cleaning. This setting is often used when the mixer cylinder body needs to withstand pressure.

E. Feeding method

It can be manually fed, fed by vacuum feeding machines, and fed by conveying machinery. In specific processes, the mixer cylinder can be made into a negative pressure chamber, and a hose can be used to suck dry materials with good fluidity into the mixing chamber for mixing, which can avoid residue and pollution in the material feeding process.

Product Features and Applications

The advantages of this machine are wide applicability, large volume, no residue discharge, and energy-saving. The cone mixer is suitable for mixing powder and powder, particle and powder, powder and a small amount of liquid, and is widely used in food, chemical, dye, pigment, pesticide, veterinary medicine, medicine, construction, new energy, metal, electronics, ceramics and other industries. This machine has a wide adaptability to mixtures, does not overheat heat sensitive materials, and can maintain the integrity of particles as much as possible for granular materials. It has good effects on the mixing of coarse powder, fine powder, fiber or sheet materials, and does not produce layer separation when mixing materials with significant weight differences and particle sizes. It also has good adaptability for the mixing of coarse, fine, and ultra-fine particles (nanoscale).

Specification parameters

1. Determine the volume of materials mixed in each batch, ranging from 0.1 to 20 cubic meters, and select equipment of corresponding specifications.

2. Select equipment to make materials, which can be divided into parts that come into contact with the material and parts that do not come into contact with the material. Other components of the equipment should maintain their original materials. The material is determined based on factors such as material properties, working conditions, and hygiene level. Generally, carbon steel and 304/316L/321 stainless steel materials are selected and the surface treatment requirements are determined according to the requirements.

3. Determine the driving capacity of the configuration based on the specific gravity, fluidity, and other properties of the material, as well as the startup standards. Starting standards include: heavy load starting and no-load starting.

4. According to the actual process situation, add auxiliary functional components such as spraying, heating/cooling, etc.

5. Design equipment opening requirements, such as feeding ports, cleaning ports, exhaust holes, etc

6. Select the discharge mode and driving method, including pneumatic, pneumatic, and electric

Important reminder: The selection of equipment is a crucial step, and detailed information on materials and process arrangements should be provided as much as possible, so that our company's professionals can provide you with high-quality technical services.

case diagram